Multiple materials can be combined through lamination, creating a composite material with unique performance attributes to suit nearly any application. Whether you need tensile strength, cushioning, adhesion, fire resistance, shock absorption or insulation from heat or cold, there is a laminated composite material that can provide an optimum solution for your product. Merryweather Foam specializes in helping our customers achieve the results they want quickly and cost effectively.

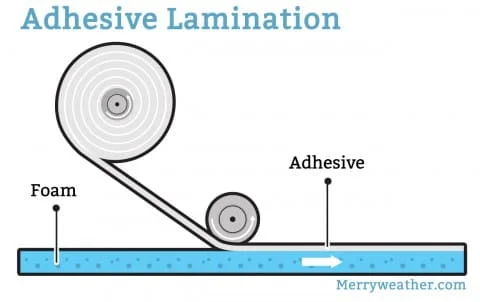

The Adhesive Lamination Process

Our specialized adhesive lamination equipment works using pressure and heat to create permanent bonds between dissimilar products. The process works by feeding rolls of two or more different materials through large rollers under precise pressure and temperature conditions. In some cases, one material may have a carefully selected adhesive pre-applied so it comes in contact with the other material during the rolling process. In other cases, an adhesive may be evenly sprayed or rolled on the materials as they unspool so they are thoroughly coated before they enter the rolling area. The new composite material is spooled at the end of the lamination process so that it can be slit to your specified lengths and widths or shipped as for use in your manufacturing facility. Regardless of the number of materials bonded and the adhesive application methodology, the material that results is permanently bonded and will have a combination of the characteristics of each material used.

Adhesive laminated materials are used in many products across multiple industries, including:

- Medical

- Industrial

- Automotive

- Appliances

- Electronics

- Packaging

Materials

Any number of materials may be used to create composites with adhesive lamination. The most frequently used materials include polyurethanes, polyurethane foams, polyethylene foams, silicones, low permeability foams for use in wet or harsh environments, closed cell PVC or rubber sponge or foam, Poron™ urethane foams, and Cellasto™ microcellular polyurethane elastomer foams. Each of these materials offers different characteristics, including

- Density

- Insulating properties

- Flexibility

- Sound absorption

- Durability

- Compressibility

- Abrasion resistance

- Permeability

- Solvent and chemical resistance

- Appearance and aesthetics

- Buoyancy and weight

- Flammability and fire retardant specs

- Regulatory approvals such as FDA, UL, ULC

- Breathability

Why You Need a Partner with Adhesive Laminating and Composite Expertise

Your application is unique, so you need a unique composite material to give you the exact performance characteristics needed to solve your customers’ problems. It requires experience and expertise to combine materials to create a composite with the right characteristics for a unique application.

At Merryweather Foam, we have more than 65 years of experience in helping customers specify exactly the right process and materials to create a composite to help your product succeed in your market. If you are interested in learning more about how our industry-leading adhesive lamination capabilities can benefit your product, contact us today.