Foam Convoluting is a process through which the surface of a piece of foam is customized to fit the requirements of a particular application. If a piece of foam in a hospital bed, for example, a unique pattern can be designed to allow for both levels of full body support and long-lasting comfort when compared to other options.

The Benefits of Foam Convolution

Foam Convoluting is a maximum yield process. Customizations to the foam are made specifically to provide the highest possible value given what a piece of foam will eventually be used for. If you use foam convolution to design a new piece of bedding, for example, the foam is customized in a way that will allow for things like:

- Enhanced levels of air circulation.

- Maximum support.

- Increased comfort while still maintaining the desired level of support, and more.

It is for these reasons that flexible foam fabrication is often used across a wide range of industries, including in both bedding and healthcare, to create things like:

- Acoustic applications, like use as sound treatment for a recording studio, thanks to their sound absorption properties.

- Privacy panels that are more durable, more attractive and more versatile than concrete alternatives.

- Office applications like ergonomic furniture, which creates a more comfortable environment for employees to maintain productive without sacrificing their health or stamina.

- Insulation designed to eliminate drafts in a building, thus keeping cool air in during the summer and warm air in during the winter, increasing the energy efficiency of the whole building and decreasing utility bills at the same time.

Foam convolution is also often used in applications like sound management, acoustic treatment and similar products in an audio recording or other entertainment environment. Depending on the pattern being used, foam convolution can absorb mid and low range sound frequencies much better than alternative options.

The Materials Used in Foam Convolution

During this process, foam can be custom fabricated in one of four ways depending on the intended goal:

- By pattern

- By the total size of the pattern being worked with

- By the depth of each intended cut that will be made

- The spacing between multiple patterns that all come together to form a single piece.

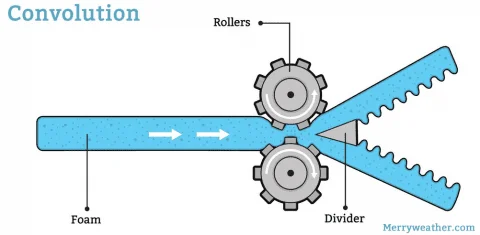

In addition to the foam itself, a number of important materials are used during the foam convolution process. A specially designed divider is often used to slice a larger piece of foam down the middle, while at the same time also creating the specific pattern that will be present on the final product. A series of rollers move a piece of foam across the divider, allowing for the process to be largely automated after all of the initial design work has taken place.

By and large, foam convolution is one of the single best ways to achieve the results that you’re after for a particular application. The products of foam convolution play an important role in the lives of millions of people on a daily basis – from acoustical engineers to patients in hospitals to people just trying to get a good night’s sleep – and the process in general is something definitely worth celebrating. Questions about Foam Convoluting or other machine processes? Give us a call–we’re happy to help!