Corporate waste isn’t just a poor business move; it’s a betrayal of loyal customers. Every piece of the production process that does not contribute to the final product means delays and high prices for patrons. Merryweather is committed to minimizing these costs and constantly improving our products and prices, which is why we have adopted lean manufacturing.

A Look at Lean Manufacturing

Lean manufacturing is a broad set of methods used to eliminate waste in the production process. While the specifics vary by company, lean methods usually involve:

- Simplifying Systems – The fewer parts a system has, the less likely it is that something will go wrong, and the less energy, resources, and oversight it takes to maintain it.

- Measuring Methodically – The more specific information a company has on production rates and times, the easier it is to set goals for improvement and meet them.

- Correcting Continuously – Lean manufacturing companies are always on the lookout for waste, making sure that every part of the production line works as well with the others as possible. They are thus able to deliver an ever-increasing level of efficiency.

Merryweather has long embraced lean methods for all stages of production and distribution. These methods have allowed us to improve profits while delivering lower costs and better services to all our customers.

It’s a Personal Journey That Begins with Me

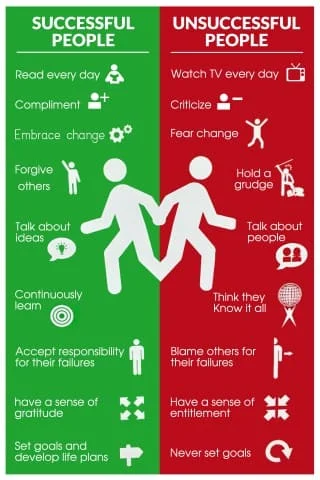

We believe that lean manufacturing begins on a personal level with our entire team–from the receiving dock to the factory floor to our executive offices. We believe in setting goals to continuously improve on both a personal and professional level. Our company culture encourages our team members to ask thoughtful questions throughout the daily scope of their job and to seek out ways that we can learn and grow together. The result of this mindset is a collective group of determined people that seek to serve of our customers.

Additional Advantages

Besides lower prices, lean manufacturing has allowed us to offer:

- Safe Jobs – Complex, wasteful systems are harder to monitor, putting employees at risk. By eliminating waste, we reduce the likelihood that our workers will be injured.

- On-Time Deliveries – Lean manufacturing systems have few delays, and when delays do occur, it is not as difficult to diagnose and fix them. This makes it easier for us to finish and deliver all orders on time.

- Endless Options – By minimizing delays in the production process, lean manufacturing allows us to quickly modify our methods and adapt in order to fill unique foam orders. It also lowers the chance that unique orders will disrupt ordinary production in ways we don’t anticipate.

- Fast Prototyping– Lean manufacturing allows us to speed up prototype testing, minimizing the time it takes to adopt new methods or sell new products.

Adopting lean manufacturing isn’t just a profitable move. It represents our commitment to treating our customers, employees, and community as well as we can. By improving efficiency, we are able to regularly make our work both better and safer, ensuring satisfaction for everyone involved.

For more information about our company or for help on your next custom flexible foam project, contact Merryweathertoday.