It’s difficult to cut curved profiles in foam and get smooth edges. Reciprocating tools tend to tear and leave unsightly steps while methods like water jet and die cutting have limitations with thick materials. In these situations it makes sense to use a vertical contour cutting machine.

Operating principle

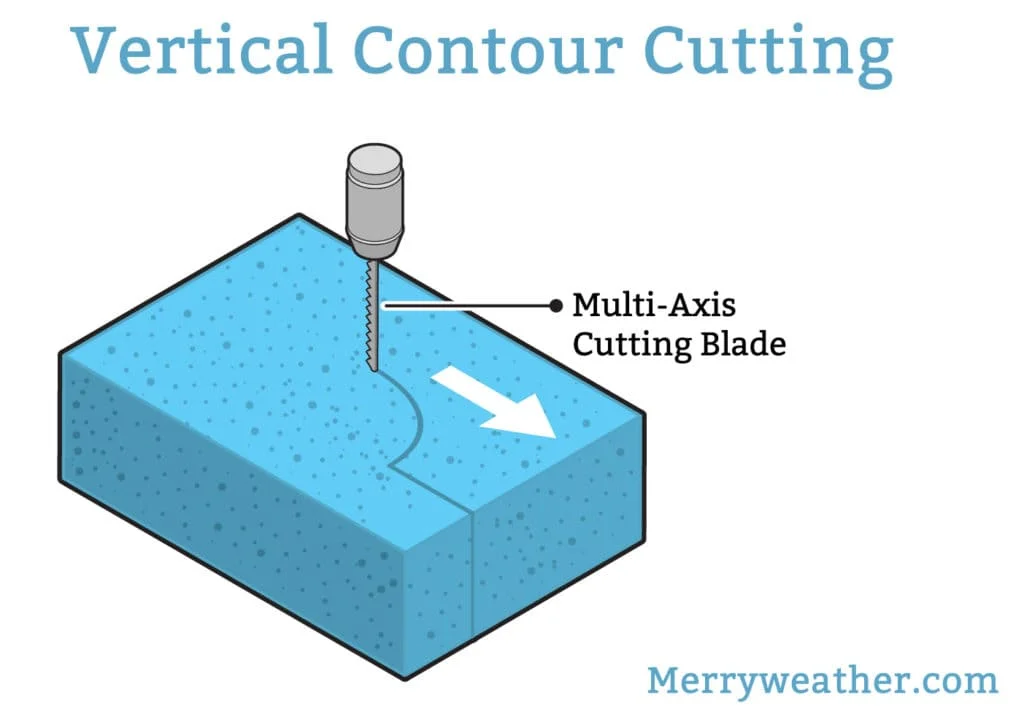

Like the band saw used in many industries, vertical contour cutting machines use a continuous steel blade held vertically under tension. The work material, (usually foam,) is placed on a flat table that moves it into the blade to make the cut. Looped over pulleys, the blade moves continuously in one direction, ensuring that it’s always cutting, (unlike with a reciprocating saw where half the motion is wasted.) Computer control over both the blade and the table motion allows production of complex shapes.

The cutting blade

As with any sawing process, the teeth shape and pitch must suit the material being cut. For foam 12 to 14 teeth per inch usually gives the optimal combination of cutting speed and edge finish. Some materials cut better with a wave form rather than teeth while others need only a flat knife blade.

The blade itself is made from high quality steel and measures 3.6 mm (0.144″) deep and just 0.6 mm (0.024″) in thickness. This geometry has two benefits. First, being very thin, there’s minimal cut waste, which also minimizes the amount of dust produced. Second, it makes the blade maneuverable.

Blade maneuverability is one area where the vertical contour cutting machine differs from a regular band saw. The contour machine can rotate the blade through 360 degrees. Combined with the shallow blade depth, this lets it turn to cut complex shapes without compressing the foam.

Motion control

The vertical contour cutting machine has three motion axes under computer control. The table moves in one direction, pushing the foam through the blade. Carried on a bridge over the table, the blade can move left and right. If the blade and table moved at the same speed a foam block on the table would be cut at a 45 degree direction.

Axis three is blade rotation. It’s this which lets the machine cut circles, corners with tight radii and complex contoured shapes. Internal holes in foam shapes are possible with just a single entrance/exit slot, (which is usually needed for fitting around bars, pipes, extrusions, cable conduit and so on.)

Machine capabilities

Merryweather’s vertical contour cutting machine handles blocks of material up to 55″ by 94″ by 25″. Cutting speed is as high as 230′ per minute, depending on material density and whether bonded or laminated. Materials appropriate for vertical contour cutting include:

- Polyurethane

- Convoluted foam

- Polyethylene

- Cross-Linked polyethylene (XLPE)

- Expanded polyethylene (EPE)

Material with densities up to 9 pounds can be cut, as can bonded layers of foam and foam laminated with either foil or textile material.

Process characteristics

- Straight, smooth sides produced on thick foam blocks.

- Cuts complex 2D shapes.

- Programmed directly from CAD files.

- “Nesting” function in software maximizes material utilization.

- No tooling, so no tooling costs or delays for tool manufacture.

- Ideal for small quantity orders

- Small “kerf” (cut width) means minimal waste and dust.

Quality results

A vertical contour cutting machine is the best way of producing smooth, straight-sided shapes in soft materials like foam. Merryweather’s machine handles large blocks of material quickly and efficiently with minimal waste. As no tooling is needed this process is ideal for both small and large quantity orders. Not sure if vertical contour cutting is the right capability for your project? Get in touch with us and we will be happy to answer any questions you have about custom foam fabrication cutting capabilities.